WEAR TESTING MACHINE

As a manufacturer, we understand that an Massager consists of numerous

critical components that all contribute to the final product quality.

Our Massagers integrate micro motors, air pump modules, graphene heating pads,

NTC temperature sensors, red LED lights, charging management ICs, DC-DC buck modules,

microcontrollers (MCU), key panels, pressure sensors, TPU/SBR composite fabrics, hook-and-loop adjustment straps,

silicone tubes and other accessories sourced from various suppliers.

To ensure the excellence of each component, we have implemented rigorous quality control

policies and integrated continuous quality monitoring throughout our entire assembly process.

Professional Massager Quality Testing Equipment

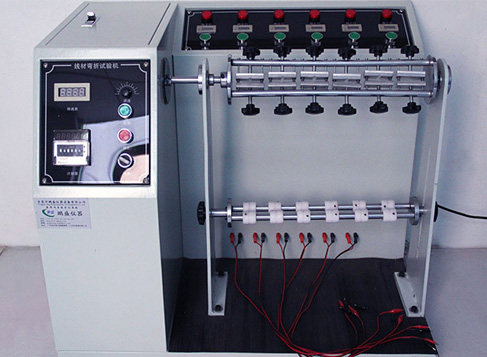

WEAR TESTING MACHINE

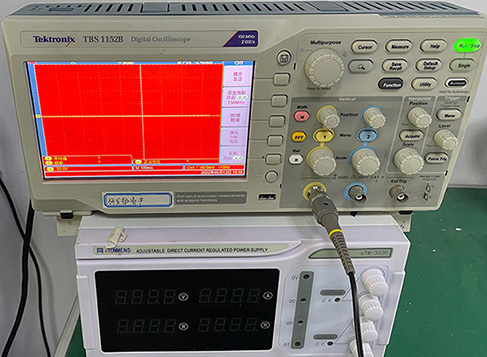

COMPREHENSIVE BATTERY TESTER

ADJUSTABLE DC POWER

SUPPLY

UNPLUGGING TEST OF THE CHARGING PORT

ELECTRIC HEATING BLOWER

DRYING OVEN

SIMULATED TRANSPORTATION VIBRATION TABLE

CABLE BENDING ENDURANCE TESTING MACHINE

SALT SPRAY TESTING MACHINE

DIGITAL OSCILLOSCOPE

RAIN TEST CHAMBER

DROP TEST EXPERIMENT

AIR TIGHTNESS TESTER

21+ Quality Inspection Items, Ensuring Excellence in Both Appearance and Function

Appearance Inspection

1. Shell Integrity Inspection

2. Fabric Adhesion Test

3. Label Clarity Check

Structure Test

1. Air Bag Pressure Resistance Test

2. Heating Element Fixation Test

3. Hook-and-Loop Strap Durability Test

4. Interface Sealing Test

Function Test

1. Multi-mode Synchronization Test

2. Temperature Gradient Test

3. Red Light Wavelength Verification

4. Auto-protection Mechanism Test

Performance Test

1. Continuous Operation Endurance Test

2. Vibration Frequency Consistency Test

3. Cross-voltage Compatibility Test

4. Pressure Distribution Uniformity Test

5. Electromagnetic Compatibility Test

6. Material Flame Retardant Test

7. Noise Control Test

8. Packaging Drop Test

9. Battery Cycle Life Test

10. Extreme Environment Test

Rigorous Quality Control at Every Production Stage

Rigorous testing of core components including electronic parts, motors, and circuit boards for performance and safety standards.

Comprehensive testing of massager shell for water resistance, sealing performance and durability to ensure reliable assembly.

Complete testing of massage intensity, mode switching, heating function, smart controls and other features for stability and reliability.

Final inspection of product appearance, accessories completeness, user manual, packaging to ensure each massager meets factory standards.

Committed to Excellence Through Rigorous Quality Standard

1. Core Component Testing: 100% inspection of all electronic components including micromotors, controllers, batteries and sensors to ensure optimal performance and safety.

2. Standard Parts Testing: Systematic sampling inspection (minimum 10% AQL) for mechanical parts. Any defects trigger immediate batch review while maintaining delivery schedules.

3. Supplier Quality Management: Strict Incoming Quality Control (IQC) procedures with detailed documentation and traceability systems.

1. 100% inspection policy for all finished products with comprehensive quality control in designated testing areas.

2. Dual QC teams conduct 21-point static and dynamic function tests. Products not meeting standards are immediately sent for technical adjustment.

3. Products certified to international standards including CE, RoHS and UL. Contact our sales team for market-specific certification details.

1. Our dedicated innovation lab continuously develops advanced massage technologies and ergonomic designs to maintain industry leadership.

2. Quarterly user experience surveys drive product improvements based on market feedback.

3. Partnerships with leading research institutions optimize therapeutic effectiveness through massage efficacy studies.

4. Smart quality management system utilizes big data analytics to enhance production processes and quality standards.