In-Process Quality Control (IPQC): A Guide to Massager Manufacturing

- By Grace

- Updated on

You get the pre-shipment inspection report, and it looks good. The container arrives, and the first few units you unbox are perfect. But as you dig deeper into the pallets, you start to find inconsistencies—a loose button here, a weak vibration there. The final inspection only checked a random sample; it completely missed the variations happening deep within the production run.

This is a classic failure of a reactive quality system. At KLCOSY, we have a core belief: quality cannot be *inspected into* a product at the end; it must be *built into* it at every single step. Our In-Process Quality Control (IPQC) is a system of live checks and balances designed to ensure the 10,000th unit is absolutely identical to the first.

In this guide, I'm going to take you onto our factory floor to show you the specific IPQC checks we perform for massager manufacturing QC, how we train our teams for obsessive consistency, and what happens the moment a unit deviates from our standard. Let's move quality from a game of chance to a matter of engineering.

Why Does Final Inspection Fail to Guarantee Consistency?

You rely on that final report to sleep at night, but it's a snapshot, not a continuous video. It can't catch the small deviations on the assembly line that lead to inconsistent performance and eventual field failures.

Relying solely on a Final Quality Control (FQC) check is like a chef only tasting a dish after it has been served to a customer. By then, it's too late to fix it. The waste—in materials, time, and reputation—has already happened. The debate of IPQC vs FQC is critical, and we believe the answer is clear. An online retail partner saw their return rate from a previous supplier skyrocket due to inconsistent heating. They told us our transparent IPQC process, which verifies temperature at the sub-assembly stage, was the key reason they switched to us.

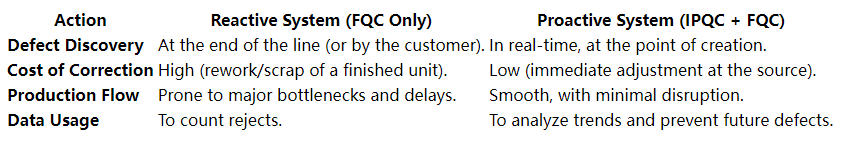

Proactive vs. Reactive: A Process Comparison

By embedding quality control on the assembly line, we shift from a culture of policing defects to one of preventing them entirely.

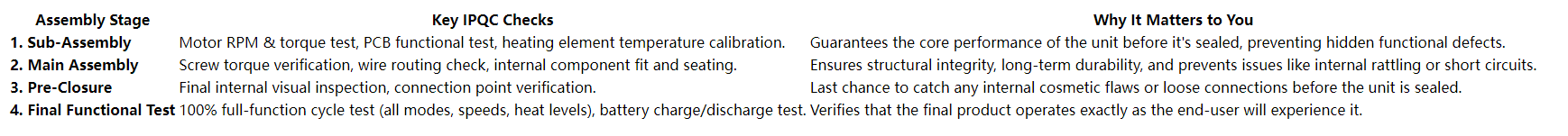

So, What Are "Quality Gates" and How Do They Work?

You need to know that your product is being built correctly, not just at the end, but at every critical point. How can you be sure internal components are installed and tested properly before they're sealed inside the unit forever?

We use a system of mandatory "Quality Gates," which are IPQC checkpoints between key assembly stages. A product cannot move to the next stage until it has passed every check at the current gate. A director at a physical therapy clinic told us our transparent Quality Gate reports gave them the documented assurance they needed to confidently use our massagers in their patient recovery protocols.

Our "Quality Gate" system is the backbone of our IPQC. It breaks down the entire massager production process into logical stages, each ending in a formal inspection. This isn't a random spot-check; it is a documented, mandatory stop. For example, before the main casing is sealed, it must pass the "Sub-Assembly Gate." Here, we test the motor, heating element, and control board *while they are still accessible*. This allows us to catch any electronic or mechanical issues where they are easiest and cheapest to fix.

Our Key Quality Gates in Massager Production

How Do You Ensure Every Worker Builds to the Same Standard?

A process is only as good as the people who execute it. How do you ensure the worker on the day shift builds a product with the exact same precision as the worker on the night shift?

Consistency comes from rigorous training, standardized work instructions, and clear visual aids at every single workstation. A corporate wellness manager said our products' consistent reliability was key; they never have to worry about a unit being out of service in their busy employee relaxation rooms. This is how you guarantee private label massager quality.

We engineer human error out of the process with a three-pronged approach. First, every operator is certified for specific tasks through a comprehensive training program. Second, every workstation is equipped with clear, visual Standardized Work Instructions (SWI) that use detailed photographs to illustrate each step. Third, an approved "golden sample" is physically present at each quality gate, providing an immediate, tangible reference for what a "perfect" unit should look and feel like at that stage.

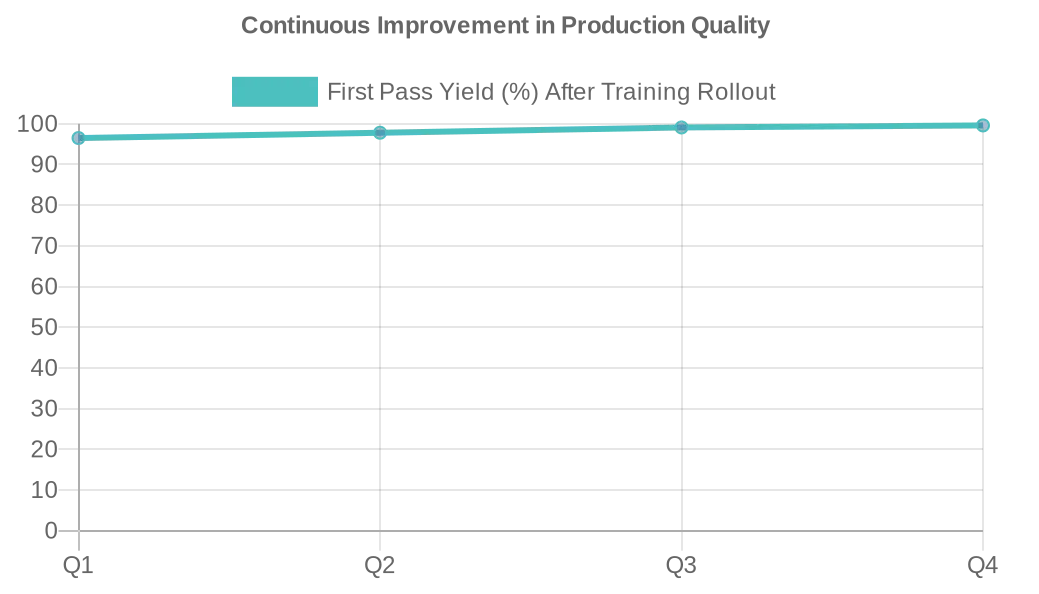

The Impact of Training on First Pass Yield (FPY)

First Pass Yield measures the percentage of units completed without any rework. It's a direct indicator of process quality. As we roll out enhanced training, we see a direct, measurable improvement in FPY, proving our system works.

True quality is not the result of a final inspection; it is the output of a meticulously designed and disciplined in-process system. How to ensure massager consistency is a question answered by mandatory Quality Gates, world-class training, and total transparency. This proactive approach ensures every unit is built right the first time, transforming manufacturing from a game of chance into a reliable science. We invite you to review the specific IPQC checklists for your product and schedule a virtual line walk-through to see our commitment to quality in action.