Portable Massager Design: A B2B Guide to Compact Engineering

- By Grace

- Updated on

As a manufacturer, I've seen countless clients fall into the "portability trap." They see the market flooded with products labeled "mini," and they ask for a smaller version of a standard design. The result? A product that's technically smaller but is still a dense, awkward brick that feels heavy in a purse and creates an uncomfortable bulge in a backpack.

Here’s the hard truth: "small" is not the same as "portable." True portability isn't just about shrinking a product; it's a dedicated engineering philosophy. It’s a series of deliberate trade-offs between size, weight, and performance. Getting this balance wrong leads to a product that sits in a drawer and gets hit with 1-star reviews for being "surprisingly heavy."

So let's move beyond the buzzwords. I'll give you the exact framework for engineering a portable massager that isn't just small, but genuinely, effortlessly portable—and I'll show you how this strategy can even lower your shipping costs.

What's the Ideal 'Travel-Friendly' Spec?

You're aiming for the highly profitable travel and on-the-go market. But what does that really mean in tangible numbers? Here's the benchmark we've established from years of user feedback:

For a product to be a truly lightweight massager, the total device weight must be under 500 grams (approx. 1.1 lbs). This is the psychological threshold where a device moves from being "a heavy item I have to pack" to "something I can just toss in my bag."

I remember a distributor who specializes in airline travel accessories came to us with a challenge: they needed a travel-friendly massager that was powerful but hit that sub-500g target for carry-on-only travelers. Our compact ODM design did exactly that, and it became their best-selling wellness product within three months.

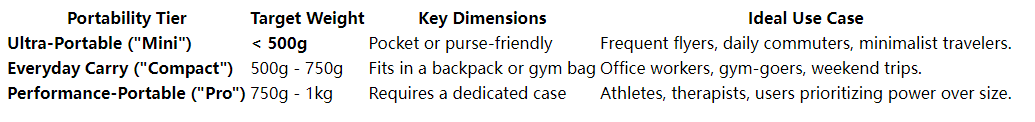

The Tiers of Portability

We categorize our designs into clear tiers, each optimized for a specific use case. This allows you to precisely target a market segment with a product engineered for their needs.

So, How Do You Reduce Weight Without Killing Performance?

This is the fundamental engineering challenge. It's easy to make a product lighter by using a smaller motor and a tiny battery, but that results in a weak device with a laughable battery life. Customers see a mini massage gun and expect "less power," but they won't tolerate "no power."

Achieving a high massager power-to-weight ratio is a game of millimeters and grams. It requires a holistic approach to compact massager design:

- Material Optimization: We replace standard plastics with advanced, lightweight polymers or, for premium models, aerospace-grade aluminum alloys.

- Ultra-Compact Layout: Our engineers obsess over the internal architecture, using 3D modeling to eliminate every cubic millimeter of wasted space.

- Component Miniaturization: We work with our supply chain to source the latest generation of miniaturized, high-torque brushless motors and high-density battery cells.

This isn't about compromise; it's about efficiency. We can build a sub-500g device that still delivers a meaningful 8mm of amplitude and 20-25 lbs of stall force—more than enough for the target user.

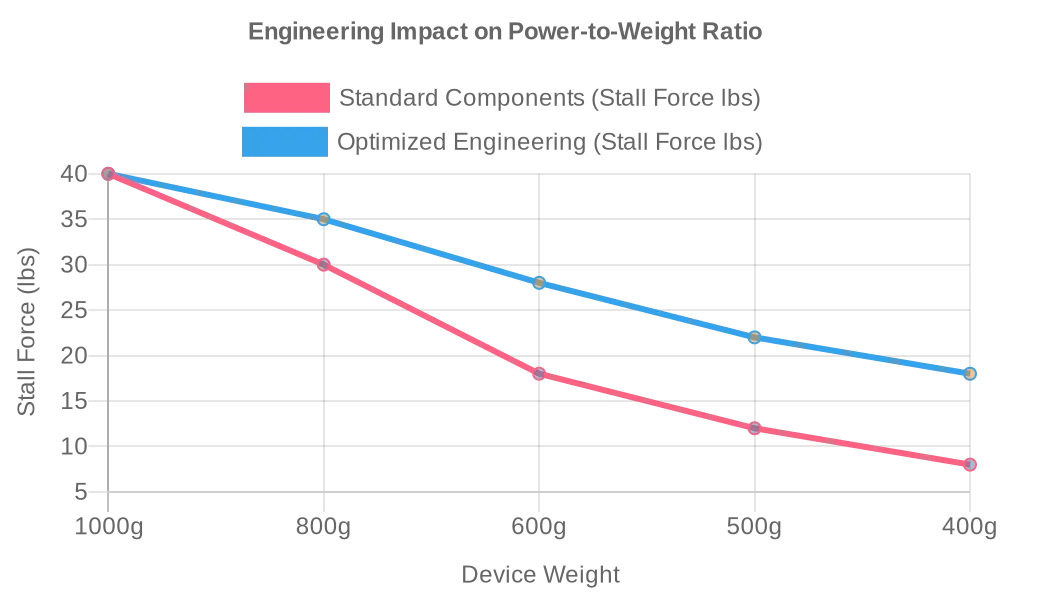

Good engineering fundamentally changes the trade-off between size and performance. An optimized design can deliver significantly more power at the same weight compared to a standard, non-optimized product.

How Does a Smaller Size Impact Your Bottom Line?

As a supply chain manager, you know this better than anyone: space is money. Every cubic centimeter you shave off your product's packaging directly impacts your shipping costs, especially for expensive air freight.

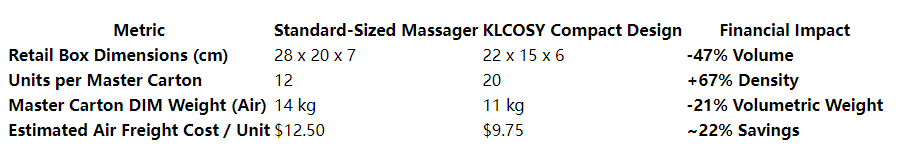

A large e-commerce seller we work with was struggling with high shipping costs from China. By switching to our "Compact" ODM model, they were able to fit 40% more units into a standard master carton. This single change reduced their per-unit air freight cost by over 22%, dramatically improving their profit margin.

Freight forwarders charge based on volumetric weight, and they will bill you for whichever is higher: the actual weight or the volume. A bulky product costs more to ship, period. Our focus on compact design extends to the packaging. A smaller product means a smaller retail box, which means we can fit significantly more units into a master carton. How a compact design lowers massager shipping costs is a critical financial lever that can translate into tens of thousands of dollars in savings over a year.

The Logistics Cost-Down Analysis

The numbers speak for themselves. A compact design isn't just a user benefit; it's a powerful financial tool for your business.

A truly portable massager is a competitive advantage that touches every part of your business, from five-star reviews to lower shipping costs. It requires a dedicated engineering partner who understands the intricate balance between size, weight, performance, and cost. Our portfolio of market-proven compact ODM designs gives you a massive head start.

Ready to leverage a proven, compact platform to win the market and lower your costs? Contact us today for the technical files and a custom logistics cost analysis based on our ultra-portable designs.