Wholesale Portable Massager: Why Choose a Chinese ODM Partner?

- By Grace

- Updated on

Are you trying to source portable massagers but feel overwhelmed by all the options? It can be tough to find a partner who delivers on price, quality, and innovation. Choosing the wrong supplier can lead to costly delays and products that just don't sell.

From my years of experience running a factory here in Dongguan, I can tell you that leading Chinese ODMs offer a powerful mix. We combine highly competitive pricing from efficient manufacturing with strong R&D, large-scale production, and complete customization services. This is all held together by a streamlined supply chain.

These advantages make a huge difference for businesses looking to launch successful products. They allow you to get high-quality, innovative massagers to market quickly and affordably. Let's explore these points further to help you find the perfect manufacturing partner for your brand.

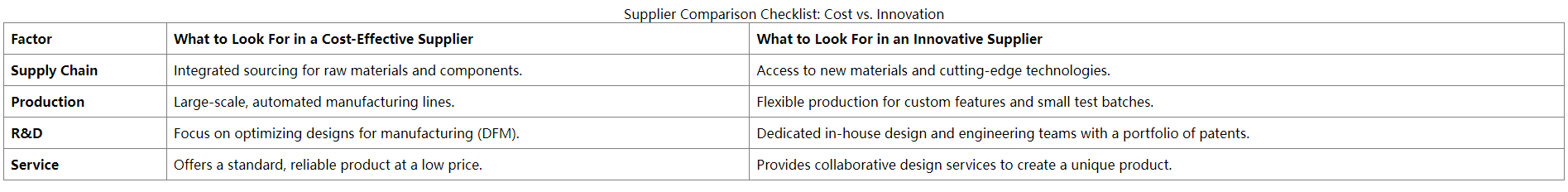

How do I compare the cost-effectiveness and innovation of different Chinese massager suppliers?

Finding a supplier that offers a great price is easy, but what about innovation? You worry that a low-cost option might be outdated, while an innovative one could destroy your margins. It feels like you have to choose between a product that sells and a product that's profitable.

I always advise my potential clients to look beyond the unit price. I compare suppliers by examining their investment in R&D and their supply chain transparency. True cost-effectiveness comes from a partner who innovates to improve efficiency, not one who simply uses cheaper materials.

Comparing suppliers requires looking at two different sides of the same coin: how they save you money and how they make you money. Cost-effectiveness is about more than just the price tag. Innovation is what gives your product a long life in the market. A great ODM partner excels at both. They use their deep industry knowledge to create a product that is both affordable to produce and desirable to customers.

Understanding True Cost-Effectiveness

A low price per unit is attractive, but it can hide other costs. A truly cost-effective supplier helps you save money across the entire production process. Here are the key areas to look at:

- Supply Chain Integration: Leading ODMs in China, especially in manufacturing hubs like Dongguan, have deep relationships with component suppliers. This allows them to get better prices on motors, batteries, and plastics. This vertical integration reduces costs and speeds up production time.

- Manufacturing Scale: High-volume production lines reduce the cost per unit. Factories that produce millions of devices a year benefit from economies of scale. They can invest in advanced automation and efficient processes that smaller factories cannot afford.

- Logistical Efficiency: An experienced ODM has a skilled logistics team. They can manage everything from factory-floor packaging to global shipping. This saves you the headache and cost of coordinating with separate freight forwarders. They find the most efficient shipping routes and handle all customs paperwork.

Gauging a Supplier's Innovation Capability

Innovation is what will make your product stand out. A supplier might claim they are innovative, but you need to see proof. Here is how you can measure it:

- R&D Team and Investment: Ask about the size and experience of their research and development team. A strong R&D department constantly works on new massage technologies, ergonomic designs, and smart features. A company that reinvests its profits into R&D is serious about innovation.

- Product Portfolio: Look at their existing product range. Do they offer a wide variety of massagers with different features? A diverse portfolio shows they can handle different technologies and market segments, from simple vibrating massagers to complex deep-tissue percussion guns with smart app connectivity.

- Prototyping Speed: How quickly can they turn an idea into a physical prototype? Modern ODMs use 3D printing and rapid tooling to create samples in days, not weeks. This speed allows you to test and refine your product faster, getting it to market before the competition.

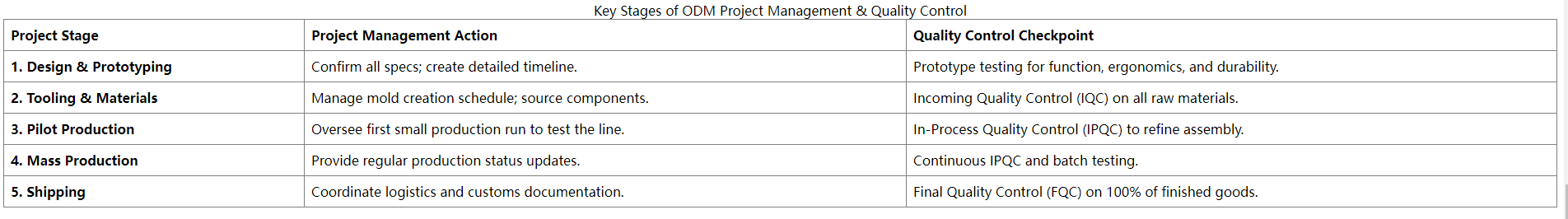

Which Chinese factories offer superior quality control and project management for custom designs?

You have a great idea for a custom massager, but you're nervous about manufacturing it overseas. Bad quality can sink your brand, and poor communication can lead to major delays. You need a partner you can trust to manage the project professionally and deliver a perfect product.

In my experience, the best factories are the ones that give you a dedicated project manager and total transparency into their quality control. I always check if a potential partner has key certifications like ISO 9001 and if they provide clear, documented reports for every stage of production, from incoming materials to final inspection.

For clients like Jeff Smith, who have deep industry knowledge, nothing is more frustrating than dealing with an unprofessional supplier. Vague answers and missed deadlines are unacceptable. A superior factory understands this. They build trust not just with promises, but with structured processes and clear communication. Their project management is proactive, not reactive. They identify potential problems before they happen. Their quality control is a system, not an afterthought. This combination is what separates a top-tier ODM from the rest and ensures your custom design project is a success.

The Foundation: Robust Quality Control Systems

Superior quality control (QC) is not just about checking the final product. It's a comprehensive system that is integrated into every step of the manufacturing process. When evaluating a factory, you should look for evidence of a multi-stage QC process:

- Incoming Quality Control (IQC): This is the first line of defense. The factory inspects all raw materials and components as soon as they arrive. This includes checking batteries for capacity, motors for power, and plastics for durability. This prevents faulty parts from ever entering the production line.

- In-Process Quality Control (IPQC): Inspectors monitor the assembly line at various stages. They check for correct assembly, secure connections, and proper function as the product is being built. This catches errors early, reducing waste and rework.

- Final Quality Control (FQC) / Outgoing Quality Control (OQC): Before any product is packaged, a team performs a final, thorough inspection. They test every function, check for cosmetic defects, and ensure the product meets all specifications agreed upon in the contract. This is the last check to guarantee every unit shipped is perfect.

The Engine: Effective Project Management

Great quality control is useless without strong project management to guide the process. For custom designs, a dedicated project manager is your single point of contact. This person is essential for smooth communication and keeping the project on track. Here’s what makes a project management system superior:

- A Dedicated Point of Contact: Instead of being passed between sales, engineering, and production, you have one person who understands your project completely. This person is responsible for answering your questions, providing updates, and solving any problems that arise. This drastically improves communication efficiency.

- Clear Timelines and Milestones: A professional ODM will provide a detailed project schedule at the beginning. This includes key milestones for design approval, tooling completion, sample production, and mass production. Regular updates ensure you always know the status of your project.

- Proactive Communication: The best project managers don't wait for you to ask for an update. They communicate proactively, especially if there are potential delays or challenges. This transparency allows for collaborative problem-solving and prevents nasty surprises, which is crucial for preventing downstream production halts for your customers.

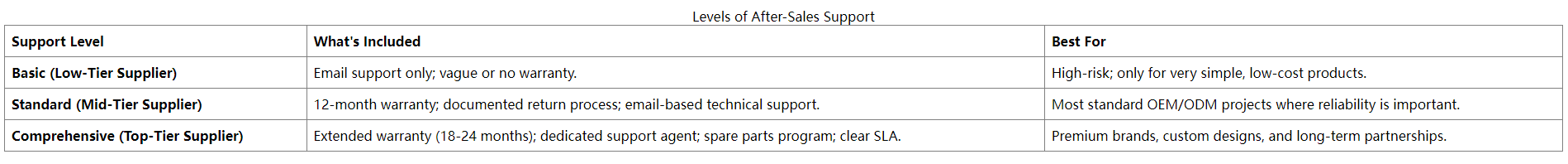

Are there Chinese suppliers known for their comprehensive after-sales service and technical support?

You've placed a large order, and the products have arrived. But what happens if an issue appears months later? You fear being left alone with faulty products and unhappy customers, with a supplier who has disappeared now that they have your money. This lack of support can destroy your reputation.

I firmly believe our relationship with a client truly begins after the first shipment leaves our factory. The best suppliers prove their value through comprehensive after-sales support. This includes clear warranty policies, a responsive technical team, and a structured process for handling any issues that come up. This is how we build lasting partnerships.

A supplier's commitment should not end when the final payment is made. For any business, especially one that sells to distributors or directly to consumers, product reliability is everything. A comprehensive after-sales service is a safety net. It shows that the manufacturer stands behind their product quality. It provides peace of mind and turns a simple transaction into a genuine partnership. Leading ODMs understand this and invest in robust support systems because they know that a client's long-term success is also their success.

What Defines Comprehensive After-Sales Service?

After-sales service is more than just a phone number to call. A truly supportive partner offers a structured program designed to resolve problems quickly and efficiently. Look for these key components:

- Clear Warranty Terms: A reliable supplier provides a written warranty that clearly states the coverage period and what is included. It should detail the process for making a claim, whether it involves repair, replacement, or credit. Avoid vague promises and insist on having the warranty terms in your contract.

- Responsive Technical Support: When a problem occurs, you need fast and helpful answers. Top suppliers have a dedicated technical support team that can help diagnose issues remotely. They should be able to provide troubleshooting guides, videos, or even live support to help your team or your customers solve common problems.

- Spare Parts Availability: For certain types of issues, a simple part replacement can solve the problem. A good ODM will maintain a stock of common spare parts like charging cables, massage heads, and batteries, and have a system to ship them to you quickly.

- Return and Repair Logistics: In case of a serious defect, the supplier should have a clear Return Merchandise Authorization (RMA) process. They should provide instructions on how to return faulty units and manage the logistics of repair or replacement in a timely manner.

How to Evaluate a Supplier's Support Before You Buy

It's important to assess a supplier's after-sales support before you commit to an order. You can do this by:

- Asking for a Service Level Agreement (SLA): Request a document that outlines their support policies, including response times, warranty details, and the RMA process.

- Checking References: Talk to their existing clients. Ask them about their experience with after-sales support. Have they ever had a problem, and if so, how did the supplier handle it?

- Posing Hypothetical Scenarios: During negotiations, ask them questions like, "What would happen if 2% of a shipment had a battery issue?" Their answer will reveal how prepared and structured their support process is.

What makes a Chinese ODM stand out in terms of design capability and user experience for portable massagers?

In a crowded market, a generic-looking massager will get lost. You need a product with a unique design that is also easy and enjoyable to use. But you worry that ODMs only offer standard templates, leaving you with a product that fails to connect with your target customers.

From what I've seen, a truly standout ODM acts more like a design partner than a simple manufacturer. We have an in-house team of industrial designers who live and breathe ergonomics, materials, and market trends. We don't just build your idea; we collaborate with you to elevate it, ensuring the final product feels as good as it looks.

A product's success is determined by the customer's experience. This experience starts the moment they see the packaging and continues every time they use the device. A great ODM understands this journey. They focus on the little details that create a premium feel: the weight and balance of the device, the texture of the materials, the satisfying click of a button, and the simplicity of the user interface. This user-centric approach to design is what turns a good product into a great one that people will love and recommend.

The Pillars of Superior Design Capability

An ODM's design capability is built on several key pillars. When you evaluate a potential partner, look for strength in these areas:

- In-House Industrial Design Team: A factory that outsources design cannot offer the same level of integration and speed as one with its own team. An in-house team works closely with engineers and production staff to create designs that are not only beautiful but also manufacturable and cost-effective.

- Expertise in Ergonomics: A portable massager must feel comfortable to hold and use. A top ODM invests in ergonomic research to design products that fit well in the hand, are easy to maneuver, and can reach different parts of the body without causing strain. They consider factors like weight distribution, grip shape, and button placement.

- CMF (Color, Material, Finish) Specialization: The look and feel of a product are defined by its CMF. A design-focused ODM will have a CMF specialist or team that can present you with the latest trends in colors, innovative materials, and high-quality finishes. This helps create a product that aligns with your brand's identity, whether it's sleek and modern or rugged and sporty.

Focusing on the User Experience (UX)

A great design is one that provides a seamless user experience. This goes beyond just how the product looks. A standout ODM focuses on the entire interaction the customer has with the product.

- Intuitive Controls: The best massagers are easy to operate right out of the box. This means simple, clear controls. Whether it's a single button that cycles through modes or a clean interface on an LCD screen, the user should never feel confused.

- User-Centric Prototyping and Testing: A top ODM doesn't just design in a vacuum. They create prototypes and conduct user testing to get real-world feedback. They observe how people hold the device, how they interpret the controls, and what they find frustrating. This feedback loop is used to refine the design until it is perfect.

- Holistic Experience: The user experience includes everything from the "unboxing" moment to charging the device. A great ODM will help you design thoughtful packaging, include a clear instruction manual, and select high-quality accessories like charging cables and carrying cases. Every detail contributes to the customer's overall satisfaction.

Conclusion

Choosing the right Chinese ODM is about finding a true partner. Look for a supplier that blends cost-effectiveness with innovation, quality control, strong support, and excellent design to help you succeed.