Supplier Quality Management: A Proactive Issue Resolution Framework

- By Grace

- Updated on

Every quality manager knows that sinking feeling in their stomach. A critical shipment is due, but your supplier has gone completely silent. This lack of B2B supplier communication is more than just annoying—it's a massive business risk. When a production issue pops up, silence breeds uncertainty, paralyzes decision-making, and eats away at the trust that holds a partnership together. Let's be honest: the real cost of a problem isn't the defect itself, but the damage done by a slow, non-transparent response.

At KLCOSY, our entire approach to supplier quality management is built on a simple belief: how a manufacturer responds to a problem is just as important as the systems they have to prevent one. Our promise to you isn't that issues will never occur—in a business as complex as manufacturing, that’s just not realistic. Our guarantee is that when they do, we have a systematic, transparent, and proactive framework for effective supply chain risk mitigation.

This article is our playbook. It’s the manufacturing issue resolution protocol that ensures you’re never left in the dark and that every challenge is handled with the structure and seriousness your business deserves.

When a Problem Occurs, Why is Silence the Real Crisis?

A production hiccup is a challenge. But a supplier who clams up and withholds information? That turns a manageable challenge into a full-blown crisis. Without timely, transparent communication, you’re flying blind. You can't make informed decisions, you can't manage your own customers' expectations, and you can't get ahead of the financial risk.

I'll never forget a conversation with a client who is now one of our biggest partners. He told us a horror story about a previous supplier who waited three weeks to inform him of a motor component shortage. That silence completely torpedoed a major product launch. When we later faced a minor supply delay on our end, we notified him within hours, providing a full report and a recovery plan. He told us, "It wasn't the problem that mattered. It was the immediate, honest communication. That's what built my trust in your supplier quality management."

The Ripple Effect of Poor Communication

When a supplier lacks supplier transparency, the hidden costs multiply fast. Suddenly you're facing inventory uncertainty, forcing you to waste capital on extra safety stock. Your marketing campaigns might be derailed, burning through your budget. But most importantly, your brand's reputation with your own customers is on the line. A supplier's failure to communicate proactively is them silently handing all the operational and financial risk directly over to you. Frankly, it's the biggest red flag in any B2B partnership.

We Don't Make Promises; We Have a Process

Many suppliers will give you a vague assurance that they'll "handle any issues." That’s not a strategy; it's a hope. A truly reliable partner replaces flimsy promises with a documented process. Our Proactive Issue Resolution framework is a pre-defined system for detection, communication, analysis, and correction. It ensures every step is structured and every action is deliberate. This system gives you predictability and control, even when things go wrong. It transforms the relationship from one based on hope to one based on operational certainty.

How We Guarantee You're the First to Know, Not the Last

The absolute worst-case scenario is hearing about a product defect from your own angry customers. Our entire B2B supplier communication protocol is designed around one core principle: that will never happen. We guarantee you'll get the information directly from us, with speed and clarity, the moment we identify a significant issue.

The Head of Sourcing for a large retail chain once told us their number one rule for partners is "no surprises." To ensure that, we provide a dedicated account manager who serves as a single point of contact. This structure ensures information flows efficiently and that factory accountability is never diffused. They know exactly who to call and trust that they will get a direct, honest answer every single time.

Your Single Point of Contact

When an issue arises, the last thing you want is to be bounced around a phone tree. Every KLCOSY partner gets a Dedicated Account Manager who is 100% responsible for all communication. This person is your advocate inside our four walls, trained in our resolution protocols, and empowered to manage the process from start to finish. Their job is to give you regular, unfiltered updates and make sure the right internal experts are mobilized to solve the problem.

Our Escalation Playbook: Structure, Speed, and Clarity

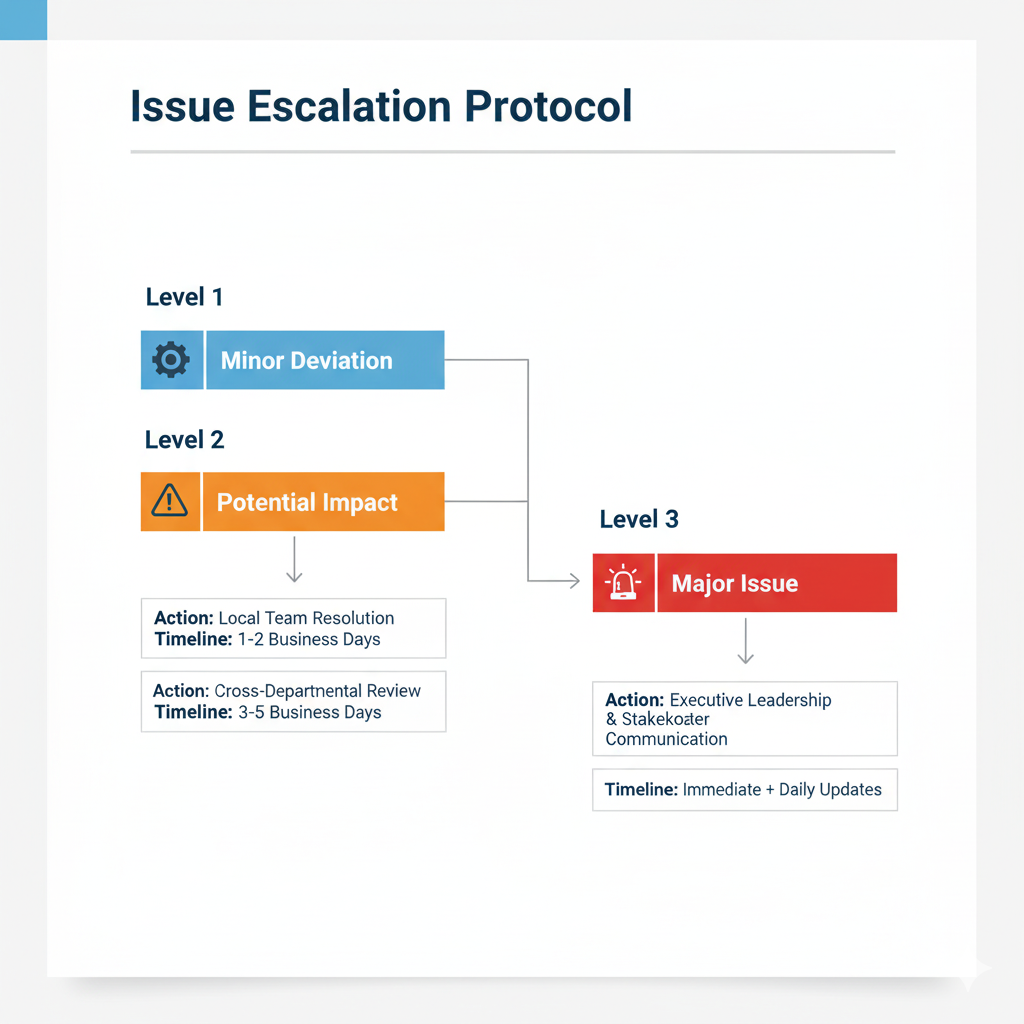

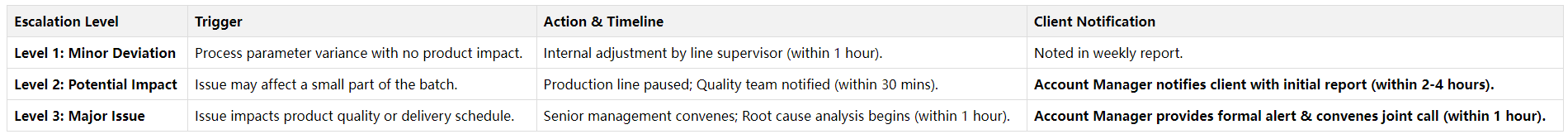

To ensure a fast and consistent response, we operate on a strict, tiered escalation protocol. The moment our real-time monitoring systems flag a deviation, this process kicks in. It’s not an improvised reaction; it's a documented procedure that defines who gets notified, what actions are taken, and the exact timeline for communicating with you. This is a core part of our supply chain risk mitigation strategy.

What Does Our Resolution Process Look Like in Action?

Clear communication is step one, but a structured resolution process is what truly protects your business. Our goal isn't just to patch the immediate problem. It's to analyze it, document it, and implement foolproof measures to ensure it never happens again.

A German distributor we work with requires a formal Corrective Action Report (CAR) for any deviation, no matter how small. After our system identified a minor cosmetic blemish on a batch, we provided them with a full CAR within 48 hours. The report detailed the root cause, the corrective action, and the preventive action. They told us the sheer thoroughness of the report—a key component of what is a corrective action report (CAR)—gave them more confidence in us than if the problem had never happened at all.

From Detection to Root Cause Analysis (RCA)

Our process begins the moment a deviation is logged. We don't just treat the symptom; we find the cure. This involves a rigorous Root Cause Analysis (RCA) to understand the fundamental "why" behind the issue. We isolate the affected products to protect your inventory, dig deep to identify the source of the problem—whether it's a machine calibration, a material flaw, or a process gap—and then implement and document a permanent corrective action. This closed-loop system ensures we don't just solve a problem for today; we eliminate it for good.