Product Traceability: A B2B Guide to Massager Supply Chain Management

- By Grace

- Updated on

Imagine this nightmare scenario. Six months after a successful launch, a credible report of a critical product failure lands in your inbox. Suddenly, your entire inventory—every unit in your warehouse, every box on retail shelves—is a suspect. Without the ability to isolate the problem, your small issue has just escalated into a potential full-scale recall, threatening your finances and your brand's reputation.

This "black box" problem, where a lack of data turns a manageable issue into a catastrophe, is the biggest hidden risk in most supply chains. At KLCOSY, we’ve engineered our production process to be a "glass box." We believe that a robust product traceability system isn't just a feature; it's a fundamental pillar of a trustworthy manufacturing partnership. It’s your insurance policy against the unknown.

In this guide, I'm pulling back the curtain on our integrated supply chain traceability system. I'll show you how we embed a "digital birth certificate" into every single unit, how it enables surgical precision during a crisis, and how it transforms the immense risk of a product recall into a manageable, data-driven event.

Why Does a Single Failure Put Your Entire Inventory at Risk?

A customer reports an issue. Is it a one-off fluke, or the tip of an iceberg? Without data, you're flying blind. You have to assume the worst: every single product you've ever sold could have the same defect.

This forces you into the financially devastating position of considering a "blanket recall." A former partner, now one of our most loyal clients, came to us after this exact scenario nearly bankrupted their product line. A minor battery issue with their old supplier forced them to recall two entire shipping containers of product because no one could identify which specific batch was affected.

In a typical "black box" factory, products are manufactured in large, undifferentiated runs. If a defect is discovered later, it is impossible to know if the root cause was a single bad batch of components, a miscalibrated machine, or a procedural error on one shift. The entire production run is contaminated with uncertainty. Effective massager recall management depends on having the data to act with precision.

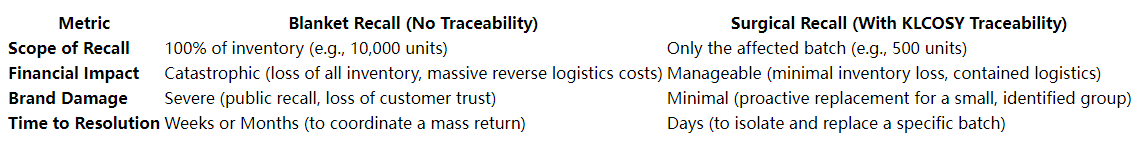

The Catastrophic Cost of a Blanket Recall

A blanket recall is a blunt instrument, whereas a surgical, batch-specific recall is a scalpel. A data-driven traceability system is what enables this precision.

So, How Does a "Digital Birth Certificate" Work for Every Unit?

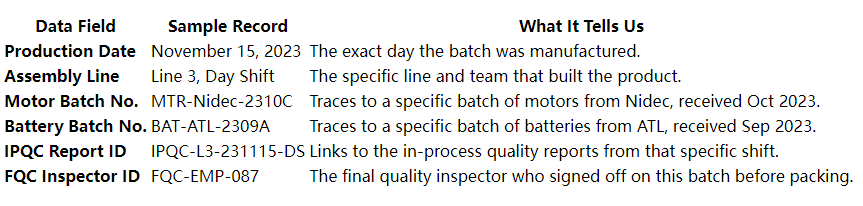

To avoid a blanket recall, you need to know the complete history of the specific unit that failed. Where did its components come from? When was it made? Who inspected it?

Every product we manufacture is assigned a unique batch code. This code is the key that unlocks a digital birth certificate for products in our system. The Quality Assurance director for a medical supply company told us, "For regulatory purposes, we have to be able to trace every component. The KLCOSY system allows us to pull the entire production history of a single batch in minutes. It's not just a feature for us; it's a core compliance requirement."

This system is built on data. The simple batch code on your product is a key that unlocks a rich, detailed record in our Manufacturing Execution System (MES). The moment a raw material batch arrives, it's assigned a lot number and scanned in. That lot number is then associated with every production run it's used in. This creates an unbroken digital thread of component traceability from the supplier all the way to the final packaged product.

Anatomy of a Digital Birth Certificate (Sample for Batch: KL88-2311A)

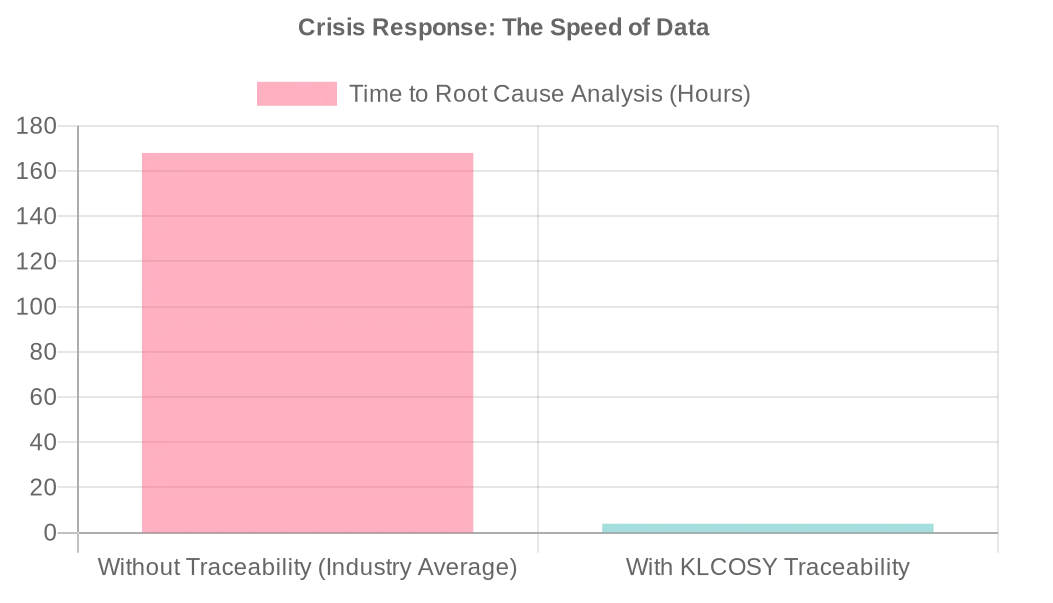

How Traceability Turns a Crisis into a Manageable Event

You've received a field failure report and the customer has provided the batch code from their product. The clock is ticking. You need to know the scope of the problem *now* to reassure your customers and stakeholders.

With the batch code, we can pinpoint the root cause in hours, not weeks. This speed transforms your response from reactive panic to proactive management. A German distributor recently faced a potential issue with a charging port. With the batch code from the single failed unit, we traced the problem to one specific tray of components used during a four-hour window. This allowed them to confidently isolate and inspect just 200 units instead of their entire inventory of 5,000. That is the power of a world-class supplier traceability system.

Here's how our crisis response process works:

- Initial Query (0-1 Hour): You give us the batch code. We enter it into our system and immediately get the "Digital Birth Certificate."

- Hypothesis (1-3 Hours): Based on the failure (e.g., "doesn't hold a charge"), we immediately focus on the most likely culprit—the battery. We pull the records for that specific battery batch.

- Cross-Referencing (3-6 Hours): We cross-reference that battery batch with all other production runs and pull its original Incoming Quality Control (IQC) report.

- Isolation & Confirmation (6-24 Hours): The data points to a potential issue with a single batch of batteries. We can now give you a definitive list of every product batch that contains a component from this suspect lot. The scope of your problem is defined and contained.

This entire process is underpinned by our robust data retention policy. We securely archive all production and quality records for a minimum of five years, ensuring that we can support you with this level of traceability long after the product has shipped.

In manufacturing, it's not a question of *if* a problem will ever occur, but *how* it will be managed when it does. A traceability system is the single most powerful tool for turning a potential catastrophe into a controlled, data-driven response. It is the defining feature of a "glass box" factory and the ultimate insurance policy for your brand. How to prevent a product recall begins with demanding this level of visibility from your manufacturing partner. We don't just build your products; we build a verifiable history for every single one.